Affiliates

Affiliates

Top Tips for Effective Thermal Custom Packaging Solutions?

Effective thermal custom packaging is crucial in today's market. According to a report by the International Packaging Association, nearly 25% of products are damaged during shipping. This highlights the importance of robust packaging solutions. Industry expert John Smith emphasizes this need: "Proper thermal custom packaging not only safeguards products but enhances customer satisfaction."

In the realm of thermal custom packaging, temperature control is vital. For perishable goods, maintaining an optimal temperature range is essential. Striking the right balance between cost and effectiveness is challenging. Many companies invest in high-quality materials but overlook design flaws. This can lead to temperature fluctuations, risking product integrity.

Innovative solutions are emerging, yet room for improvement remains. The market for thermal custom packaging is projected to grow by 8% annually. Companies must adapt to changing customer demands. As competition increases, those who prioritize effective packaging will thrive. Meanwhile, the need for balance between sustainability and performance is more crucial than ever.

Understanding the Importance of Thermal Custom Packaging Solutions

Thermal custom packaging solutions play a vital role in preserving quality. They protect temperature-sensitive products during transport. This is essential for food, pharmaceuticals, and electronics. Customers expect their items to arrive in perfect condition. Using effective packaging is not just a choice; it’s a necessity.

One key tip for effective thermal packaging is selecting the right materials. Insulation should match the product requirements. For instance, using bubble wrap for fragile items can prevent breakage. However, some materials may not provide sufficient heat protection. Always test the packaging under various conditions to ensure it meets expectations.

Monitoring temperature during transport is equally important. Consider using data loggers to track conditions in real-time. This can highlight weaknesses in your packaging strategy. Adapting quickly can save products and costs. Organizations often underestimate the impact of packing efficiency. It deserves regular review and adjustment to keep up with changing demands.

Key Materials for Effective Thermal Packaging Design

When creating effective thermal packaging, choosing the right materials is crucial. Insulation options vary. Common materials include Styrofoam, bubble wrap, and fiberboard. Each has its pros and cons. For instance, Styrofoam provides excellent insulation but can be difficult to recycle. Bubble wrap is lightweight but may not offer enough thermal protection for long shipments.

Consider using phase change materials (PCMs) as well. They absorb and release heat, maintaining a stable temperature. This is helpful in sensitive shipments. Additionally, flexible packaging solutions can adapt to various shapes. This customizability often improves thermal efficiency. However, remember that not all materials are suited for every product.

When designing thermal packaging, think about the environment. Sometimes, the cheapest option may not be the best. Reflect on how your choices impact sustainability. Striking a balance between cost and effectiveness can be challenging. Continuous testing and adjustments are essential for optimal results. Each product may require a different approach. Experiment to find the perfect fit for your thermal packaging needs.

Tailoring Thermal Packaging to Specific Products and Conditions

When it comes to thermal packaging, customization is key. Each product has unique requirements. For example, pharmaceuticals need strict temperature controls, while food items may require insulation and durability. Understanding these specific needs can avoid spoilage or damage during transport.

Temperature regulation is not the only consideration. Humidity levels also play a critical role. A well-designed thermal package should address moisture control. This can be challenging. Some products react poorly to humidity or temperature fluctuations. Finding the right materials can be trial-and-error. It's essential to test packaging methods to ensure safety and quality.

After implementing packaging solutions, it's vital to review their effectiveness. Are temperatures staying stable during transport? Do materials hold up under stress? If not, adjustments are necessary. Thermal packaging is not one-size-fits-all. Ongoing assessment helps tailor solutions to evolving needs.

Sustainability Considerations in Thermal Custom Packaging Solutions

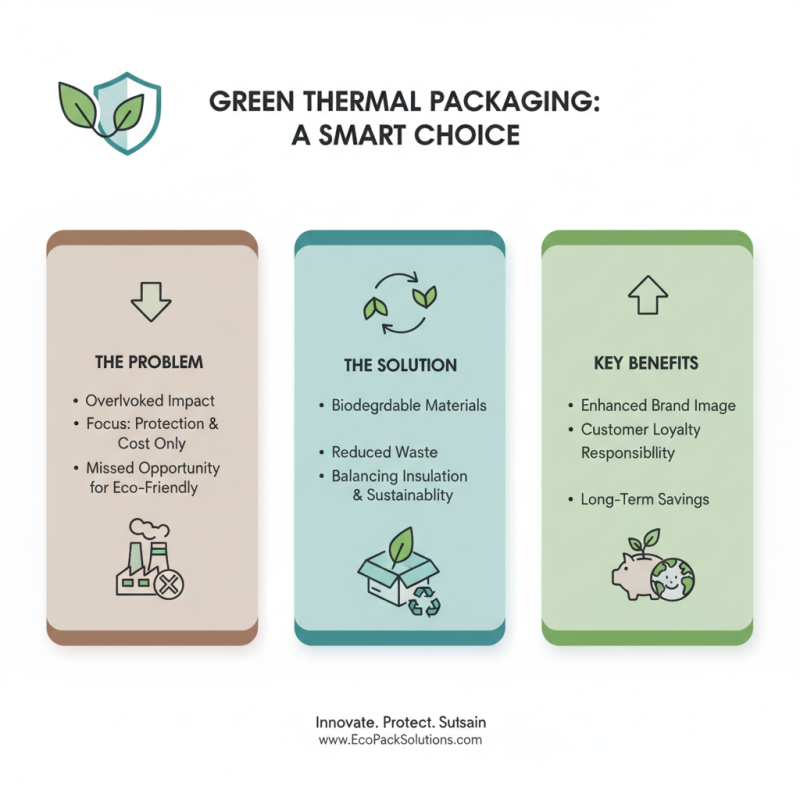

Sustainability is crucial in thermal custom packaging solutions. Many companies overlook its impact. They might focus solely on protection and cost, neglecting eco-friendly options. This is a missed opportunity. Materials play a significant role here. Biodegradable materials can reduce waste significantly. Yet, finding the right balance between insulation and sustainability can be challenging.

Recycling is essential in this process. It limits raw material use and lowers environmental footprints. Unfortunately, many consumers are unaware of recycling guidelines. This lack of awareness can lead to recycling confusion, making the process ineffective. Businesses should educate customers about proper disposal. This not only helps the environment but also boosts brand image.

Another aspect is energy efficiency in production. Factories must adopt greener practices. However, implementing these can be costly and complex, raising concerns for smaller businesses. The struggle is real. Companies need to invest in sustainable technologies without compromising quality. Flaws in execution can arise, requiring continual reflection and adjustment. Finding the right solution takes time and effort, but the long-term benefits are clear.

Best Practices for Testing and Evaluating Thermal Packaging Performance

When evaluating thermal packaging performance, thorough testing is crucial. Ensure that the materials provide effective insulation. Use specific temperature ranges relevant to your products. Measure how long the package maintains desired temperatures. This includes both hot and cold items.

Consider using real-world shipping scenarios for evaluation. Test packages during extreme weather conditions. Monitor performance over various transit times and distances. It's important to analyze results in detail. Sometimes, packages might fail to maintain temperature for required durations. Reflecting on these failures can lead to improved designs.

Don’t forget about user feedback. Customers often notice flaws in packaging that manufacturers overlook. Their insights can highlight areas needing attention. Testing is not just about numbers but also about understanding usability. A package might perform well theoretically but fail in practical situations. Adjustments based on feedback can lead to better packaging solutions in the long run.

Related Posts

-

What is Medical Device Packaging Trends and Innovations in 2026

-

Top Customer Experience Packaging Strategies to Enhance Your Brand Loyalty

-

Top Benefits of Fiber Molded Packaging for Sustainable Packaging Solutions

-

Top 5 3PL Packaging Trends to Watch in 2025 for Your Business

-

How to Choose the Right Wood Packaging for Your Products?

-

Top 10 3PL Packaging Solutions You Should Consider for Your Business