Affiliates

Affiliates

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality

In the world of manufacturing and product development, ensuring that items reach their destinations in pristine condition is paramount. Clean room packaging has emerged as a critical solution for industries ranging from pharmaceuticals to semiconductor production. As Dr. Emily Zhang, a leading expert in clean room technology, aptly puts it, "The integrity of a product is only as strong as its packaging, especially in environments where contamination can lead to catastrophic failures." This statement underscores the essential role that clean room packaging plays in maintaining product safety and quality.

Clean room packaging not only protects products from environmental contaminants but also ensures compliance with stringent industry standards. By employing specialized materials and controlled environments, manufacturers can significantly reduce the risk of contamination during the packaging process. As we delve into the best clean room packaging solutions, it becomes evident that these practices are not merely a precaution but a necessity for companies dedicated to providing high-quality products.

In an era where consumer safety and product reliability are non-negotiable, investing in effective clean room packaging methodologies is crucial. The focus on achieving optimal product safety and quality is transforming industries, making it imperative for stakeholders to stay informed about the latest advancements and solutions available in clean room packaging.

Understanding Clean Room Packaging: Definition and Importance

Clean room packaging is a critical practice in industries where product safety and quality are paramount. Defined as a controlled environment designed to minimize particulate contamination, clean room packaging ensures that products, particularly sensitive items such as electronics, pharmaceuticals, and medical devices, remain uncontaminated during production and storage. This specialized packaging process utilizes materials and techniques that adhere to stringent cleanliness standards, thereby safeguarding the integrity and reliability of the products.

The importance of clean room packaging cannot be overstated. Contaminants such as dust, microbes, and chemical residues can compromise product performance, leading to potential failures and safety issues. By implementing effective clean room packaging solutions, manufacturers can mitigate these risks, enhance product longevity, and comply with regulatory requirements. This proactive approach not only protects the product but also bolsters customer confidence, reinforcing the brand's reputation for quality and reliability in the market. It is an essential component of any rigorous quality assurance strategy.

Key Features of Clean Room Packaging Solutions for Product Safety

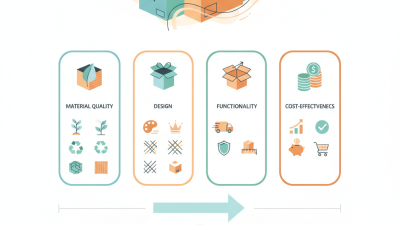

Clean room packaging solutions are essential in industries where contamination can severely compromise product integrity and safety, such as pharmaceuticals and electronics. These solutions are designed to maintain a controlled environment, ensuring that products remain free from particulates, microorganisms, and other environmental factors. Key features of effective clean room packaging solutions include using high-quality materials that resist contamination, as well as designs that allow for easy handling while prioritizing the protection of the product within.

Another critical aspect is the implementation of stringent quality control measures throughout the packaging process. This includes maintaining cleanroom standards during production, where air filtration systems and controlled humidity levels are utilized to sustain a sterile environment. Packaging must also be customizable to fit specific product requirements, whether that involves tailored sizes or specialized sealing methods that prevent any exposure to outside elements. Such features not only enhance product safety but also ensure consistent quality, ultimately leading to greater customer satisfaction and trust in the product’s reliability.

Types of Clean Room Packaging Materials and Their Applications

Clean room packaging is essential in various industries, particularly in pharmaceuticals, biotechnology, and electronics, where product integrity is critical. The materials used in clean room packaging play a pivotal role in maintaining product safety and quality by protecting them from contamination and environmental factors. Among the most common materials are polyethylene, polypropylene, and specialized films that are designed to be free from particulates and biological contaminants. According to a report by MarketsandMarkets, the global cleanroom packaging market is expected to reach $3.58 billion by 2025, reflecting a growing demand for high-quality packaging solutions in controlled environments.

Different types of clean room packaging materials serve various applications. For instance, blister packs made of PVC or PETG are widely used in pharmaceutical packaging, ensuring sterility and ease of access. Additionally, static shielding bags, often made from polyethylene compounded with conductive agents, are crucial in the electronics sector for protecting sensitive components from electrostatic discharge (ESD). A study by the Institute of Packaging Professionals indicates that the adoption of appropriate clean room materials can reduce contamination risk by up to 80%, underscoring the importance of selecting the right packaging solutions tailored to industry-specific requirements.

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality

| Packaging Material | Application | Benefits | Environmental Considerations |

|---|---|---|---|

| Polyethylene (PE) Bags | Electronics and semiconductor components | Moisture barrier, clean and contaminant-free | Recyclable but may require specific facilities |

| Foam Inserts | Medical devices and sensitive equipment | Shock absorption and cushioning protection | Can be made from recycled materials |

| Cleanroom-Compatible Boxes | Pharmaceutical products and research samples | Sterile, dust-free, and chemical resistant | Often recyclable, depending on materials |

| Static Shielding Bags | Electronic components and assemblies | Prevents electrostatic discharge (ESD) | Disposal considerations for ESD materials |

| Labeling Solutions | All cleanroom packaging | Clear identification and traceability | Use eco-friendly inks and adhesives |

Regulatory Standards and Compliance in Clean Room Packaging

Clean room packaging is essential for industries where product safety and quality are paramount, such as pharmaceuticals, biotechnology, and electronics. Ensuring compliance with regulatory standards is crucial to maintaining the integrity of products during storage and transportation. Different sectors have specific guidelines that dictate the cleanliness levels of the environment and the materials used for packaging. For example, the FDA and ISO standards provide frameworks that companies must adhere to, ensuring that harmful contaminants do not compromise product safety.

When selecting clean room packaging solutions, it's vital to consider materials that are not only compliant but also compatible with the product being packaged. Some materials can introduce contaminants, which is why knowing the requirements of the specific industry is essential. Additionally, conducting routine audits and staff training can help maintain compliance with these standards and ensure that packaging processes are continually improved.

**Tips:** Always keep updated with the latest regulatory changes to ensure ongoing compliance. Regularly assess your packaging materials and processes against industry standards, and invest in employee training to foster a culture of quality and safety. Collaborating with experts in clean room environments can also provide valuable insights into best practices and innovative solutions for packaging.

Best Clean Room Packaging Solutions for Ensuring Product Safety and Quality

Best Practices for Implementing Clean Room Packaging Solutions

Implementing clean room packaging solutions is essential for maintaining product safety and quality, especially in industries such as pharmaceuticals, biotechnology, and electronics. The stringent requirements for these environments necessitate packaging that prevents contamination and ensures integrity throughout the product's lifecycle. According to the Institute of Environmental Sciences and Technology (IEST), nearly 70% of contamination incidents occur during packaging and handling processes. Therefore, adopting best practices for clean room packaging is crucial to mitigate these risks.

One effective approach is to train personnel rigorously on clean room protocols and packaging techniques. Regular training sessions on contamination prevention and proper handling procedures can significantly reduce the risk of human error. Additionally, using advanced packaging materials that offer barrier protection against particulate, microbial, and chemical contamination can enhance the overall safety of products. Reports from the Controlled Environment Association indicate that implementing such materials has been shown to reduce contamination rates by up to 50%.

Tips: Always verify that packaging materials are compliant with industry standards such as ISO Class cleanroom protocols. Consider investing in automated packaging systems to minimize human intervention, as automation can lead to increased efficiency and reduced contamination risks. Furthermore, regular audits of packaging processes can help identify potential weaknesses and areas for improvement, ensuring ongoing compliance with safety standards.